Pictures of TFL-400III Told

High-power laser burn welding of beryllium copper mold inserts

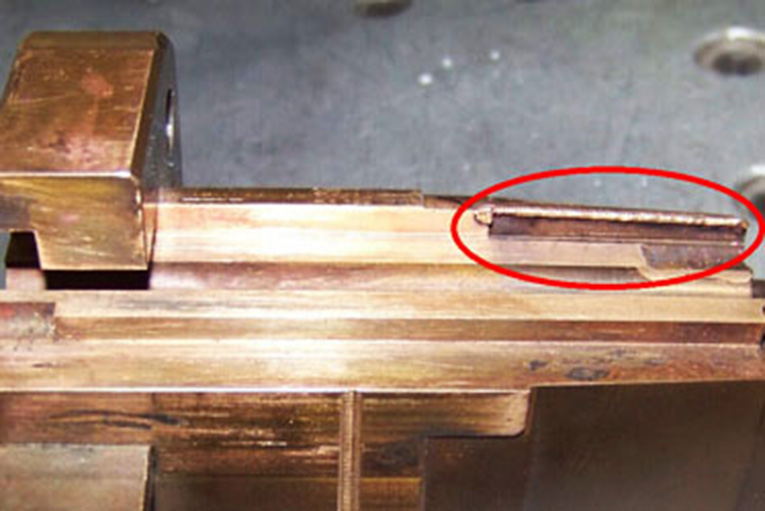

High-power laser welding of purple copper electrode

Laser head can be turned, can weld the mold deep cavity and mold side wall

Mold laser welding machining principle

The principle of laser processing: the laser emitted by the laser generator passes through a series of processing, and the energy is highly concentrated in a small range after the lens focus. If the processed material absorbs the laser well, the material in the irradiated area will quickly heat up because of absorbing the energy absorption of the laser. Depending on the properties of the material (such as melting point, boiling point, the temperature causing chemical changes), the workpiece will undergo a series of physical or chemical changes, such as melting, gasification, generation of oxides, discoloration, and so on. This is the principle of laser processing.

Advanced processing mode, high efficiency

Compared with the traditional machining, the focused laser is like a very fine invisible tool, which "burns" the surface of the local area of the object point by point. It is characterized by no contact with the workpiece, no mechanical extrusion or mechanical stress, so it does not change the physical properties of the processed articles; because the size of the laser focusing is small, the thermal influence area is small, and the processing is fine, some conventional processes can be completed.

Applied range

Scope of application

YHL-400 mold laser welding machine is a high-power laser welding machine independently developed by Yuehe Machinery Co., LTD. The second generation precision dual lamp power supply independently developed by Yuehe and the touch screen pumping drive power supply make the operation more convenient. The main machine has manual lifting of laser head and electric lifting of workbench button, which can realize laser welding of different thickness molds. This model is more suitable for all kinds of high-power, large-area laser repair molds. Because of the high laser power, laser welding beryllium copper mold, aluminum mold or aluminum parts. In the large-area laser repair mold, thicker welding wires can be used, and the laser welding efficiency is greatly improved.

Product Parameter

Model | YHL-400 |

Laser wave length | 1064nm |

Concentration cavity reflector | Gold gilt cavity |

Laser power | 300W |

Pulse length | 0.1-20ms |

Laser frequency | 0-99Hz |

The scope of light spot regulation | 0.3-3mm |

Coolant passage | 3p one-piece |

Table stroke | 125x100mm |

Rated effect | 14KW |

Electricity demand | Standard three phase 380v+5%/50Hz/40A |

External size | Host:680x1350x1400mmCooling-water machine: 600x900x1400mm |