One-piece die laser welding machine TFL-200 YT / TFL-400 YT processing sample pictures

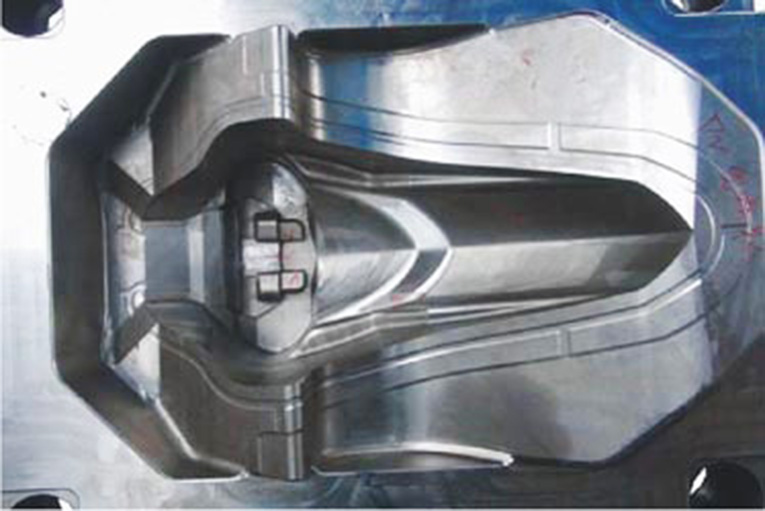

Auto door panel mold laser repair

Large mold laser repair site

Large die size for laser repair

Large die size for laser repair

Mold laser welding machining principle

The principle of laser processing: the laser emitted by the laser generator passes through a series of processing, and the energy is highly concentrated in a small range after the lens focus. If the processed material absorbs the laser well, the material in the irradiated area will quickly heat up because of absorbing the energy absorption of the laser. Depending on the properties of the material (such as melting point, boiling point, the temperature causing chemical changes), the workpiece will undergo a series of physical or chemical changes, such as melting, gasification, generation of oxides, discoloration, and so on. This is the principle of laser processing.

Advanced processing mode, high efficiency

Compared with the traditional machining, the focused laser is like a very fine invisible tool, which "burns" the surface of the local area of the object point by point. It is characterized by no contact with the workpiece, no mechanical extrusion or mechanical stress, so it does not change the physical properties of the processed articles; because the size of the laser focusing is small, the thermal influence area is small, and the processing is fine, some conventional processes can be completed.

Applied range

Common laser integrated mold laser welding machine YHL-200 YT / YHL-400 YT is a variety of function fusion of new mold laser welding machine, for super large plastic mold laser welding, medium injection mold laser welding, small plastic mold laser welding, die casting die laser welding and other mold can achieve super precision repair, help you solve the large car mold repair problem, do not need mold move, electric bench and stereo rotating laser head perfect combination, rod control movement realize easy laser repair large mold, but also retained the traditional manual workbench super precision repair mold function.

Product Parameter

Model | YHL-200YT | YHL-400YT |

Laser wave length | 1064nm | 1064nm |

Concentration cavity reflector | Ceramic concentrating cavity | Metal gilt cavity |

Rated laser power | 200W | 400W |

Single point of energy | 45J | 90J |

Pulse length | 0.1-20ms | 0.1-20m5 |

Laser frequency | 1-99H2 | 1-99HZ |

The scope of light spot regulation | 0.3-2mm | 0.3-2mm |

Electric work table travel trip | 200X200mm | 200X200mm |

Manual work table traveltrip | 125X100mm | 125X100mm |

Laser head longitudinalstroke | 0-560mm | 0-560mm |

Laser head pitch Angle | Horizontal is down by 45 degrees | Horizontal is down by 45degrees |

Laser head lift (electric) | 0-200mm | 0-200mm |

Laser head rotation andswing amplitude | A 180-degree effective span | A 180-degree effective span |

Rotate the laser focus head | Three-dimensional 360 degrees | Three-dimensional 360 degrees |

Coolant passage | A 1.5P integrated water machine | 3p integrated water machine |

power rating | 6KW | 14KW |

Power supply demand | Threephase electricity220V/38±5%/50HZ/30A | Threephaseelectricity 380V+596/50HZ/40A |

Appearance size of the host | 1600*650*1280mm(Long * width *height) | 1600*700*1400 (Long * width *height) |

Water machine appearancesize | 540*650*780mm (Long * width *height) | 600*900*1300mm (Long * width* height) |