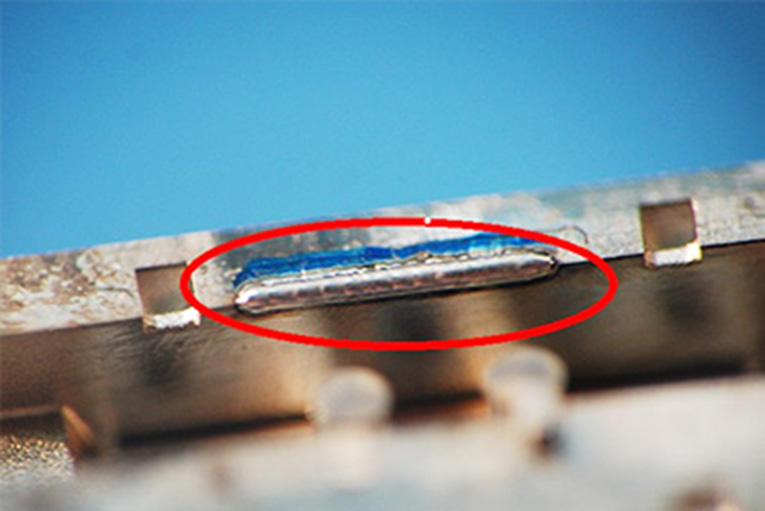

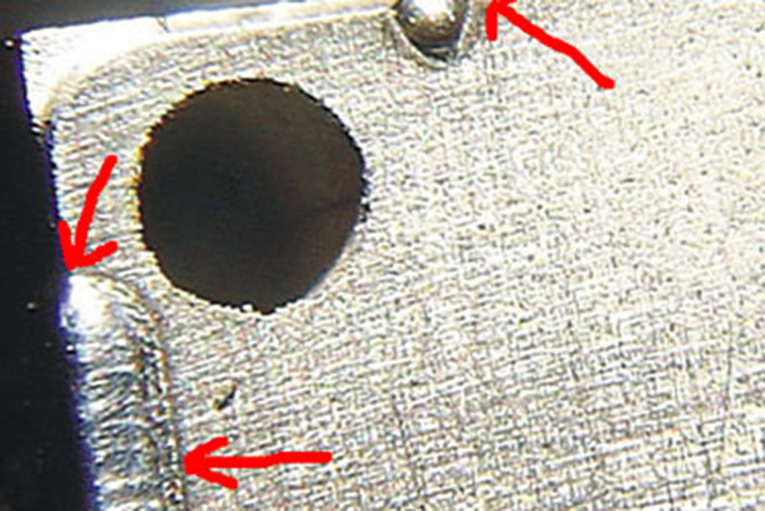

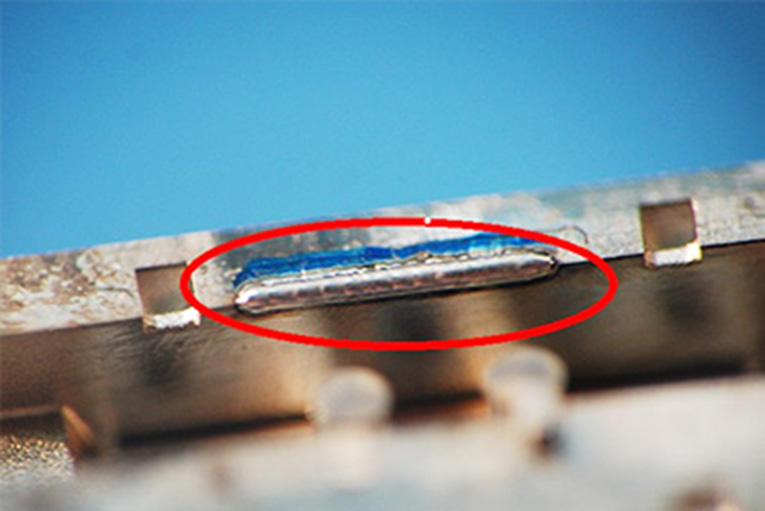

Sample picture

Principle of mold laser welding machining

The principle of laser processing: the laser emitted by the laser generator after a series of processing, through the lens focusing the energy is highly concentrated in a small range, if the processed material on the laser absorption is better, then the irradiated area of the material will absorb the energy of the laser and rapidly heat up. Depending on the properties of the material (such as melting point, boiling point, temperature at which chemical changes occur), the workpiece will undergo a series of physical or chemical changes, such as melting, gasification, oxide generation, discoloration, and so on. This is the principle of laser processing.

Advanced processing mode, high efficiency

Compared with traditional machining, the laser after focusing is like a very fine invisible tool, the surface of the local area of the object is "burned" point by point, it is characterized by no contact with the workpiece, no mechanical extrusion or mechanical stress, so it will not change the physical properties of the processed goods; Due to the small size of the laser focus, the small heat-affected area, and the fine processing, some processes that cannot be achieved by conventional methods can be completed.